OUR CAPABILITIES

AirBoss Engineered Products offers integrated support for compound development, product design, prototyping, and production.

Our engineers, material scientists, and operations teams help customers streamline design, testing, and fabrication processes across a wide range of industries.

With decades of experience and advanced in-house capabilities, we provide reliable solutions for complex challenges in rubber manufacturing.

Let us help you rethink the way you work with rubber.

Pre-Production Modeling & Design Capabilities

Pre-Production Modeling & Design

We support the early design phase with CAD and CAE tools that help validate part geometry, performance, and manufacturability. These tools allow for faster iteration and improved alignment with production requirements.

Mold Flow Analysis

Our engineers use mold flow simulation tools to evaluate how compounds behave during the molding process. This allows us to optimize tooling and part design in advance—minimizing production risks and improving first-pass yield.

Material Development & Formulation

Our compound development team works closely with customers to identify materials that meet performance targets such as durability, flexibility, chemical resistance, and thermal stability. We draw on decades of formulation experience and an extensive compound library.

Tooling & Equipment Optimization

We maintain in-house tooling and repair capabilities to support efficient production and minimize downtime. This allows us to fine-tune processes, make real-time adjustments, and ensure consistent part quality across production runs.

Product Testing and Prototype Fabrication Capabilities

Process Optimization & Operational Control

Our manufacturing systems are designed for process stability, throughput efficiency, and cost control. From early-stage design through full-scale production, we focus on eliminating waste and optimizing output without compromising quality.

Advanced Automation

Our automated manufacturing cells handle high-volume, repetitive processes with precision and consistency. These self-contained systems improve cycle times, reduce variability, and support scalable production across multiple part types.

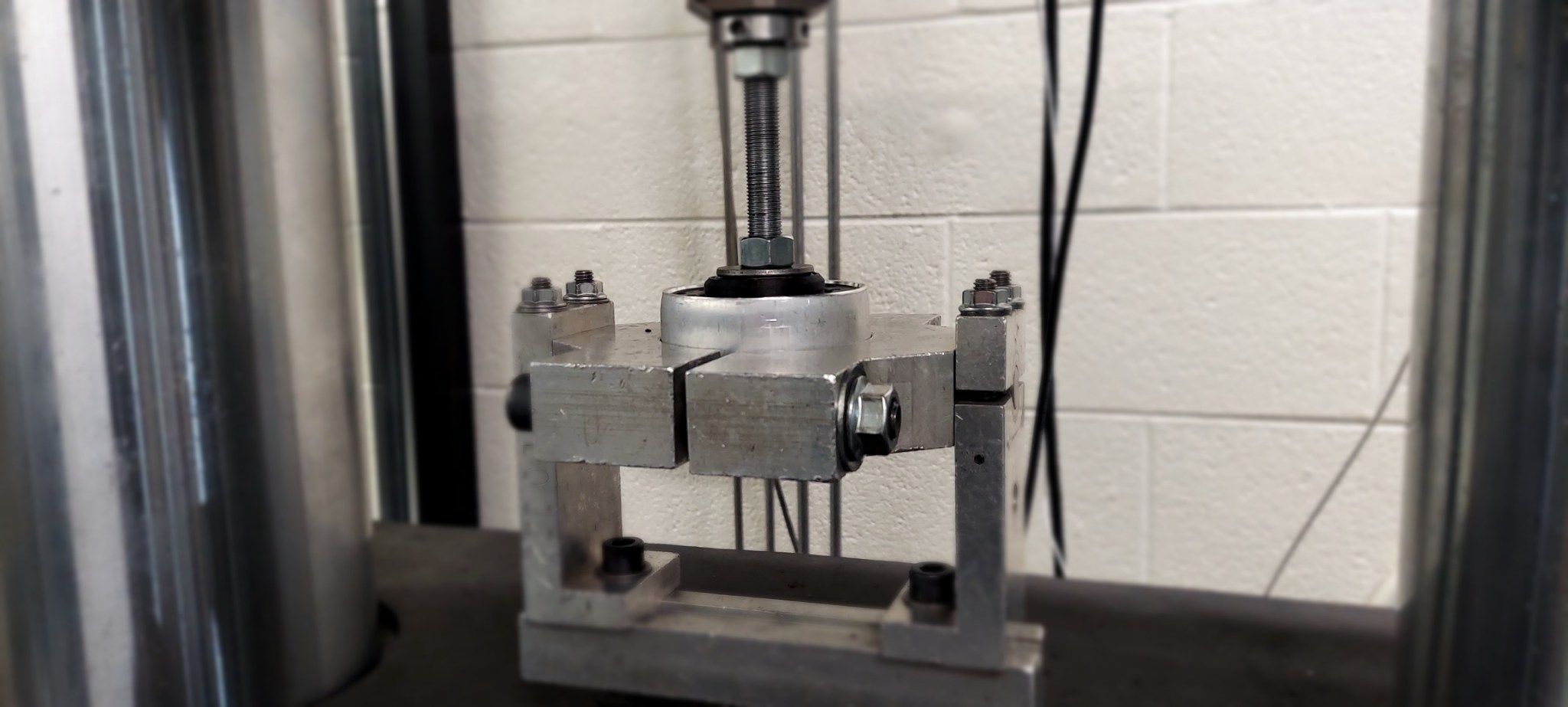

Testing & Rapid Prototyping

We provide in-house prototyping and testing capabilities to accelerate development cycles and improve decision-making. With 3D printing and test rigs, we can rapidly evaluate part designs and generate data to guide final production.

Fabrication & Assembly

Our in-house team manages component fabrication and assembly to ensure quality control, reduce lead times, and simplify the supply chain. We specialize in complex molded components with integrated finishing and packaging.

Engineering Solutions for Real-World Demands

Rubber is our foundation—but our value lies in the ability to turn complex performance requirements into scalable, tested solutions.

We support customers across transportation, defense, healthcare, aerospace, construction, and more with reliable materials, precision manufacturing, and hands-on engineering support.